Capabilities of Our Industrial Machines

Here at SPOTTER, we have the capabilities to handle most of your custom textiles and cut foam needs. Our industrial sewing machines are calibrated and tuned to the high standards required by outdoor rock climbing. They are able to handle all types of heavy materials and textiles. Our foam cutting machines can deliver results tailored to whatever needs your foam project calls for! Any size, shape and density can be custom formulated.

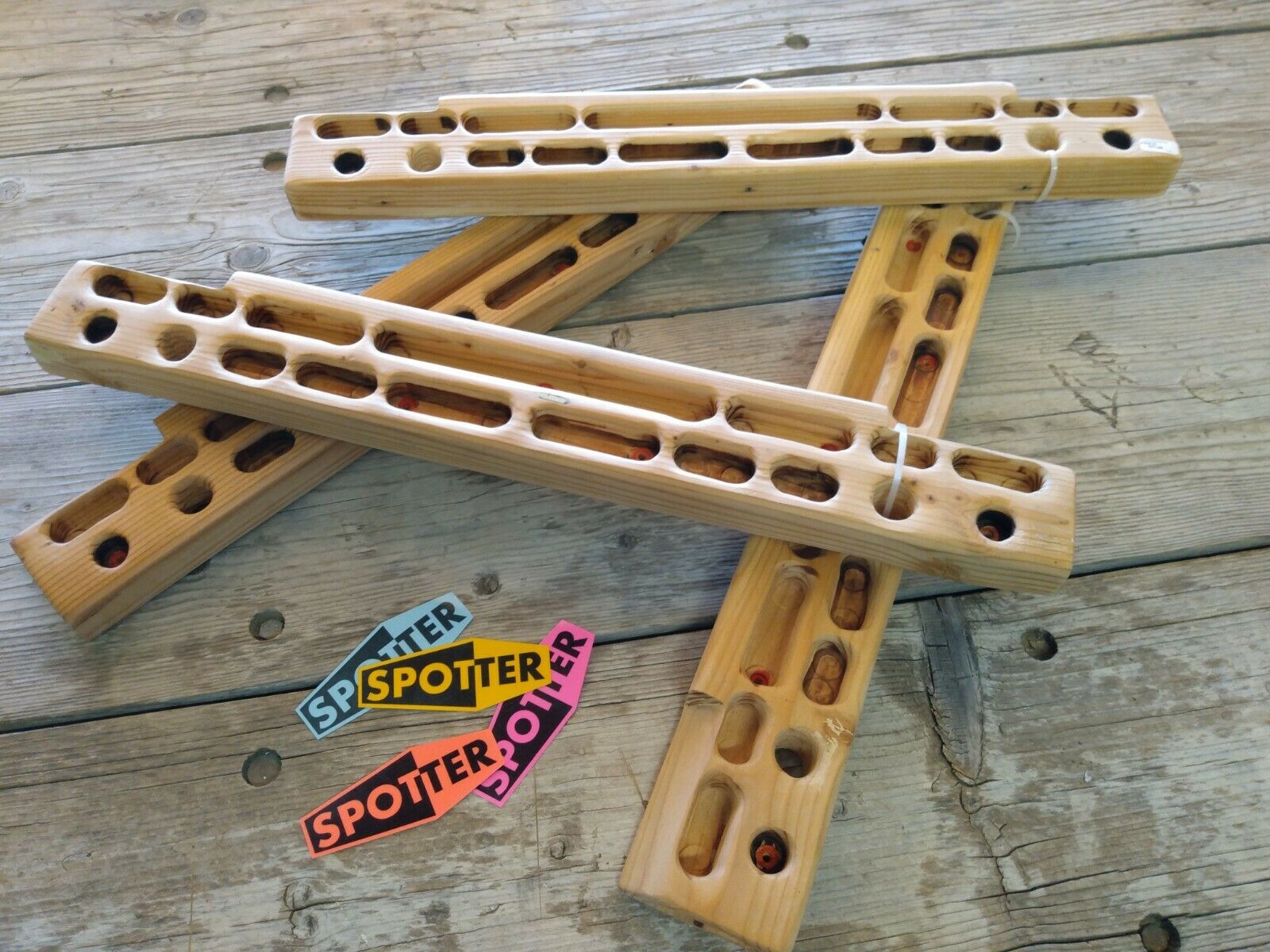

SEWING MACHINES

![]()

Straight Stitch Tex90

The Consew 105 is a heavy duty industrial single-needle, lockstitch machine that is ideal for heavy-duty sewing applications. This machine has a maximum sewing speed of 1,700 stitches per minute, making it a great choice for sewing through thick fabrics, such as Cordura, nylon, leather, and thick canvas.

Zig-Zag Bar Tack Tex69

The Consew CN 2053 R-1 is a high-speed, single-needle, lockstitch machine that is ideal for heavy-duty sewing applications. This machine has a maximum sewing speed of 2,000 stitches per minute, making it a great choice for sewing through thick fabrics, such as denim, leather, and canvas. The CN 2053 R-1 features a large bobbin and vertical-axis hook that allows for efficient thread handling and prevents thread breakage. The machine also has a built-in automatic lubrication system, which ensures smooth and consistent performance over time. Additionally, the machine’s presser foot can be easily adjusted to accommodate different thicknesses of fabric, allowing for greater versatility in sewing applications.

One of the key features of the Consew CN 2053 R-1 is its heavy-duty construction. The machine’s frame is made of cast iron, which provides stability and durability during operation. The machine also comes with a large workspace, which is ideal for handling large projects. Another notable feature is the machine’s safety clutch mechanism, which prevents damage to the machine in the event of thread or needle breakage. The CN 2053 R-1 also comes with an assortment of accessories, including several types of presser feet, bobbins, and needles, making it a versatile and practical investment for anyone who needs a heavy-duty sewing machine for commercial or industrial applications.

FOAM MACHINES

Horizontal Cutter

When choosing foam products, you want a high-quality solution that is precision cut to meet your exact specifications. With our high performing and precise horizontal foam cutting machine, we promise you will get just that with every order. Let’s take a closer look at the operation of this high performing machine.The automated horizontal saw is the first stop for conventional open-cell foam and memory foam once it arrives at our facility. This horizontal foam cutting machine is used to slice buns into more manageable sheets that are then sold as-is or processed into a more refined end-product on another piece of machinery. Featuring an automated 86″ x 132″ table that pulls the buns through the 2-1/4″ wide blade, the horizontal saw can handle foam buns 51″ tall and 88″ wide, though the average bun size runs closer to 40″ in height and 76″ in length, making it incredibly versatile and functional for a range of creations. Depending on outfitted features, a horizontal foam cutting machine can weigh anywhere from 4,500 to 6,000 pounds. This heavyweight champion is certainly high performing enough to earn its place in any foam cutting facility.

When choosing foam products, you want a high-quality solution that is precision cut to meet your exact specifications. With our high performing and precise horizontal foam cutting machine, we promise you will get just that with every order. Let’s take a closer look at the operation of this high performing machine.The automated horizontal saw is the first stop for conventional open-cell foam and memory foam once it arrives at our facility. This horizontal foam cutting machine is used to slice buns into more manageable sheets that are then sold as-is or processed into a more refined end-product on another piece of machinery. Featuring an automated 86″ x 132″ table that pulls the buns through the 2-1/4″ wide blade, the horizontal saw can handle foam buns 51″ tall and 88″ wide, though the average bun size runs closer to 40″ in height and 76″ in length, making it incredibly versatile and functional for a range of creations. Depending on outfitted features, a horizontal foam cutting machine can weigh anywhere from 4,500 to 6,000 pounds. This heavyweight champion is certainly high performing enough to earn its place in any foam cutting facility.

True to its namesake, the horizontal cutter operates along a flat plane with no articulation of the blade. Using this saw, we are able to slice sheets as thin as 1/4″ with impressive precision and speed. The products most commonly produced by this machine are mattresses, though every non-reticulated/non-latex open-cell foam will pass through the horizontal saw at some point. We also slice bulk sheets for upholsterers and other businesses with this horizontal foam cutting machine. This machine is a workhorse that creates a high volume of foam products and cuts thanks to the high performing design and operation of the machine. While it is precise, it can leave a few rough edges on select products which our team will then work diligently to remove before the product is sold. As one of the most standard machines in a foam producing factory, there is no denying the horizontal cutter is a mainstay for foam creations.

Vertical Cutter

Foam is one of the most versatile materials on the market and the applications are pretty much endless. When it comes to getting the right shape and cut of the foam product, we utilize several different machines. With our vertical foam cutting machine, we are able to cut a variety of types and densities to get the right product outcome for our customers. Let’s take a closer look at this versatile machine.When making custom products or simply reducing the size of sheets cut by the horizontal saw, our vertical foam saw gives us precision finishing capabilities. With multiple tables of varying dimensions, we have the ability to handle projects of all sizes simultaneously with our vertical foam cutting machine. Mainly used for tailoring products instead of processing bulk forms, we put this saw to work fabricating individual or short-run custom products, such as tapered seating cushions, or forms like body wedges and knee pillows. This is one of our most commonly used machines since these are popular items with customers looking to utilize our high-quality foam in practical applications for their lives.

Foam is one of the most versatile materials on the market and the applications are pretty much endless. When it comes to getting the right shape and cut of the foam product, we utilize several different machines. With our vertical foam cutting machine, we are able to cut a variety of types and densities to get the right product outcome for our customers. Let’s take a closer look at this versatile machine.When making custom products or simply reducing the size of sheets cut by the horizontal saw, our vertical foam saw gives us precision finishing capabilities. With multiple tables of varying dimensions, we have the ability to handle projects of all sizes simultaneously with our vertical foam cutting machine. Mainly used for tailoring products instead of processing bulk forms, we put this saw to work fabricating individual or short-run custom products, such as tapered seating cushions, or forms like body wedges and knee pillows. This is one of our most commonly used machines since these are popular items with customers looking to utilize our high-quality foam in practical applications for their lives.

Unlike automated machines, the vertical saw requires its operator to manually guide foam through the blade, much like woodworking band saws. Our skilled team works with care and speed to achieve the right result for our customers using this reliable vertical foam cutting machine on a variety of projects. The 3/4″ wide blade is articulated with a 45 degree range of motion that allows the operator to taper or grade each piece individually for even more attention to detail. However, it can only cut along the plane set by the blade’s angle; it is unable to form contoured curves which can make it somewhat limited in some respects. These machines can weigh 2,300 to 3,000 pounds, depending on outfitted features. Well worth its weight and size thanks to the performance it renders, our vertical foam cutting machine offers great precision when coupled with our skilled team at the helm.

CNC Horizontal

Finding the right foam products is easy with our selection of affordable items. Have you ever wondered how we create these products? With a focus on precision and accuracy, we use machines such as the commercial CNC machine to get the best result for your order. Let’s take a closer look at the foam CNC machine.

Finding the right foam products is easy with our selection of affordable items. Have you ever wondered how we create these products? With a focus on precision and accuracy, we use machines such as the commercial CNC machine to get the best result for your order. Let’s take a closer look at the foam CNC machine.

The best thing about a foam CNC machine is the impressive precision it offers with every creation. With several horizontal computer numerical control (CNC) machines under our roof, including both oscillating and continuous saws, we have the capability to craft incredibly precise products in-house to keep our prices at a competitive figure. Able to finely adjust measurements, the CNC machines are perfect for detailing products to exact consumer specifications for flawless outcome sure to please. Even with their precision, CNC cutters are just as powerful as the vertical and horizontal saws, able to handle up to 8LB density foam, depending on the variety.

Using computer programming to map out the desired design, a commercial CNC machine produces clean lines and sharp angles that would be impossible to replicate by hand. We are able to produce customer-specific products from the buns, as well as a variety of sheet patterns and contoured products, using this high performing machine. The continuous-blade machines have tables that rotate the bun automatically, allowing for the 3D rendering of a product without manual manipulation, and a blade that can be “twisted” 360° to work around the bun which gives impressive versatility and options. The oscillating machines require that buns be rotated manually, but the blade has no angle restriction, as it utilizes a back-and-forth sawing motion for added precision and ease of achieving the desired outcome. Additionally, all CNC saws have all been re-engineered since their arrival for improved performance and less downtime, as well as lower sound levels, to help with precision, speed, and overall quality of the finished product. This machine can be used for a variety of outcomes to ensure you always get the most precise, accurate foam cut as possible.

CNC Vertical

Getting foam products for your every need has never been easier with our selection of affordable items. None of our products would be possible without the machines used to create them. In our journey to bring you the highest quality products, we use machines such as our vertical CNC to achieve the best result! Let’s take a closer look at this state-of-the-art apparatus.

Getting foam products for your every need has never been easier with our selection of affordable items. None of our products would be possible without the machines used to create them. In our journey to bring you the highest quality products, we use machines such as our vertical CNC to achieve the best result! Let’s take a closer look at this state-of-the-art apparatus.

Our vertical CNC machine is designed for precision due to the high-speed cuts performed by its blade. Because of the efficiency of this machine we are able to keep our prices at competitive figures. Since we are able to finely adjust measurements in the computer, the vertical CNC machine is perfect for detailing products in a highly efficient manner. This machine allows for accurate contours and shaping due to the blade being able to turn a full 360 degrees.

Once the cut is programmed into the system, the vertical CNC can cut accurate lines and sharp angles that would be impossible to replicate by hand. Using this highly efficient machine, we are able to cut mattresses, mattress toppers, and foam pit cubes in a timely manner. This machine is also built perfectly to produce foam for large dining room seating, stadium seating, or other mass seating applications. The belt on the machine also makes quick work of foam by allowing it to move back and forth as needed as the blade cuts. Additionally, all CNC saws have been re-engineered since their arrival for improved performance and less downtime, as well as lower sound levels, to help with precision, speed, and overall quality of the finished product. With so many products made by our factory, the vertical CNC cutter has become crucial in increasing productivity and efficiency for all of our customer’s needs.

Die Cutter

Foam is a material that can be used for a range of applications to great effect. Aside from knowing which foam is right for you, getting a product that matches with your exact specifications is key to a useful product. With our foam die cutting press, we can achieve that perfect outcome of precision and quality you seek. Let’s take a closer look at die cutting foam using this reliable machine.In simplest terms, our die cutter operates like a large-scale cookie cutter, great for cutting exact shapes out of foam. Dies, also known as plates, are made by setting thin, finely serrated blades into wood to create a cutting pattern. Sheets of foam are placed over the plates and compressed by up to 80 tons of pressure. The foam is forced down over the blades, cut to shape, and released, creating a form exactly matching the design on the plate with stunning precision and accuracy. With a table measuring 76″ x 32″, multiple designs can be inset on one large plate to produce forms quickly and economically. The die cutter features a simultaneous two-button safety system required to execute a pressing, greatly reducing any chance of accidental operation.

Foam is a material that can be used for a range of applications to great effect. Aside from knowing which foam is right for you, getting a product that matches with your exact specifications is key to a useful product. With our foam die cutting press, we can achieve that perfect outcome of precision and quality you seek. Let’s take a closer look at die cutting foam using this reliable machine.In simplest terms, our die cutter operates like a large-scale cookie cutter, great for cutting exact shapes out of foam. Dies, also known as plates, are made by setting thin, finely serrated blades into wood to create a cutting pattern. Sheets of foam are placed over the plates and compressed by up to 80 tons of pressure. The foam is forced down over the blades, cut to shape, and released, creating a form exactly matching the design on the plate with stunning precision and accuracy. With a table measuring 76″ x 32″, multiple designs can be inset on one large plate to produce forms quickly and economically. The die cutter features a simultaneous two-button safety system required to execute a pressing, greatly reducing any chance of accidental operation.

Because of the die cutter’s ability to produce multiple forms in a single pressing, it is mainly utilized to produce bulk quantities at rapid speed. Where the waterjet machine may make hundreds of one item, the die cutter is capable of making tens of thousands in approximately the same amount of time. Detailed high-volume orders, like form-fitting packaging for delicate items, are produced on the die cutter, as well as novelties and toys like the giant foam hands seen at sporting events. With our high-quality materials and our foam die cutting machine at the ready, getting the high quality, precision cut product you need has never been easier or more attainable. Let us create something for you today using this reliable machine!

Waterjet

When it comes to applications for foam, the possibilities are truly endless. To create the foam products you know and love, we use several machines to achieve the flawless results you receive when you order. One of the most commonly used pieces of equipment we employ is a water jet foam cutting machine. Let’s take a closer look at the waterjet foam cutter and its capabilities.

When it comes to applications for foam, the possibilities are truly endless. To create the foam products you know and love, we use several machines to achieve the flawless results you receive when you order. One of the most commonly used pieces of equipment we employ is a water jet foam cutting machine. Let’s take a closer look at the waterjet foam cutter and its capabilities.

Harnessing the power of highly-pressurized, abrasive-free water, and the precision of computer programming, our waterjet cutters are able to create products possessing a high degree of detail. Many people are surprised to find out that a waterjet foam cutter can offer the same if not better precision over blades. The key to how this machine works is the use of highly pressurized water streams to achieve the desired results. With a jet of water pressurized at 50,000 psi, traveling at three times the speed of sound, we are able to cut through foam products up to 4″ thick. For perspective, the cutter is able to slice through a 1/2″ piece of plywood on our standard foam-cutting settings with a jet only .005″ in diameter. After a design is programmed, the foam is placed on a bed of 7″ corrugated plastic that breaks up the jet’s powerful stream. The nozzle moves over the sheet, tracing the form’s outline with the water, cutting through the foam cleanly. The overall operation of this machine is designed to be streamlined and efficient with every use to ensure a great outcome.

While both the waterjet and the die cutter provide a high degree of precision, the waterjet cutter is geared toward lower-volume product runs. This is because the time it takes to trace every cut is measured in minutes, while a single pressing on the die cutter takes seconds, but because the water jet foam cutting machine only requires computer programming, it carries a shorter lead-time than the die cutter and doesn’t require expensive press plates. Waterjet jobs are often limited-volume products like prototypes, specialized packaging forms, gaskets, and toys.

Convoluter

We take great pride in the foam products we produce for our customers. With a focus on precision cuts for a range of foam types, our machines are the heart of our operation in creating the high-quality solutions you expect with every purchase. Our foam convoluter machine is one of our more specialized machines. Let’s take a closer look at this important powerhouse.

We take great pride in the foam products we produce for our customers. With a focus on precision cuts for a range of foam types, our machines are the heart of our operation in creating the high-quality solutions you expect with every purchase. Our foam convoluter machine is one of our more specialized machines. Let’s take a closer look at this important powerhouse.

Convoluter cutters are responsible for producing our instantly-recognizable eggcrate foam from solid sheets without generating any waste. While it sends a blade through the center of a sheet of foam like a horizontal cutter, the foam convoluter also compresses the foam as it is fed through the machine, using a studded roller to increase pressure during the cut. The areas under the studs are compressed to greater degree than other areas of the foam as the blade passes through. When released from the pressure of the rollers, the compressed areas form the peaks of the eggcrate and areas under less pressure form the valleys. And since the blade passes through the middle of the foam, you wind up with two interlocking eggcrate sheets from one solid sheet!

Our foam convoluter has an 84″ width, allowing us to cut mattress toppers to any size, one of the most popular uses for eggcrate foam. The machine feeds automatically with no limit to the sheet’s potential length, provided it remains less than 84″ in width. We are able to adjust the height of the foam’s peaks from 1″ to 3″, and vary the thickness of the base, which is the distance from the bottom of a valley to the bottom of the actual sheet. Uses for the eggcrate foam include the aforementioned mattress toppers, padding and backing for seating and wheelchairs, packaging, and even sound-deadening materials cut from acoustical foam. With the use of our foam convoluter we are able to work quickly to create the products our customers need for their applications.

Skiver

When it comes to foam products, the possibilities are endless. With our selection of high-quality foam types for various applications, you are sure to find the solution for your needs. When creating our products, we use several different machine types to achieve the end result. Let’s take a look at how our foam skiving machine works as well as the products it can cut.

When it comes to foam products, the possibilities are endless. With our selection of high-quality foam types for various applications, you are sure to find the solution for your needs. When creating our products, we use several different machine types to achieve the end result. Let’s take a look at how our foam skiving machine works as well as the products it can cut.

Every foam has its own unique properties in terms of density. A heavier density denotes a foam that is stronger and more durable but also hard to cut. When it comes to cutting our densest materials, the foam skiving machine is the right tool for the job. To cut our densest foam rubber, such as closed-cell foams and plastic foams, we employ the foam skiver because it can handle cutting through the densest of materials without wear and tear while still offering a precise cut. With the ability to slice sheets as thin as 1/16″ or as thick as 5″, it operates exclusively on a horizontal plane. Because of the density of the materials cut with the skiver, the blade is substantial, measuring 3.3″ wide and .04″ thick. Given the demands high-density materials place on a cutting machine, the foam skiving machine is incredibly powerful and constantly self-sharpens its blade. The fact that is it handles tougher materials while still maintaining its own blade makes it one of the most valuable pieces of equipment we use.

The machine is manually fed and can handle sheet widths up to 76″, with no limit in length. For especially long sheets, the skiver is able to be fed from rollers. The skiver requires some programming when setting desired sheet thicknesses, but not to the degree of a CNC machine, as the saw blade remains stationary once programmed. Since the skiver can only cut horizontally, products are often trimmed down to size afterward on vertical saws, waterjet cutters, or die cutters. Products produced on the skiver include high-density packaging, flotation devices, and sports matting and padding.

Hot Wire

The use of foam products spans several industries thanks to the overall versatility and usefulness of the material. With the different kinds of foam and all the products it can be used, as well as the need for various cuts and textures to be created such as eggcrate, the need for reliable machines is evident. While most machines use blades to create the precision and cut, a blade is not the only way to go about cutting foam. With our hot wire cutter, we can cut polystyrene foam with surprising precision without the use of blades. Let’s take a closer look at how the hot foam cutter works.

The use of foam products spans several industries thanks to the overall versatility and usefulness of the material. With the different kinds of foam and all the products it can be used, as well as the need for various cuts and textures to be created such as eggcrate, the need for reliable machines is evident. While most machines use blades to create the precision and cut, a blade is not the only way to go about cutting foam. With our hot wire cutter, we can cut polystyrene foam with surprising precision without the use of blades. Let’s take a closer look at how the hot foam cutter works.

Made to be a powerful, well-oiled machine performing at high capacities, our foam cutter wire equipment uses special technology to achieve results. Heated by electrical resistance, our CNC hot wire cutter’s tensioned Ni-Chrome wire passes through polystyrene foam effortlessly while creating precision shapes and contours. The 1/64″ wire carves a path through the foam only 1/16″ wide as the foam evaporates around it. Our hot wire cutter has an operating area of 96″ x 96″ and can handle blocks of foam 48″ tall. Wire temperature is adjustable, and many cutters reach almost 400 degrees Fahrenheit. To prevent scorching, we typically reduce temperatures to 90 percent, about 350 degrees. On extremely delicate projects, we may turn the heat down to 35 percent, approximately 137 degrees.

After the cuts are programmed, the wire simultaneously operates on horizontal and vertical planes to produce contours and smooth edges. It is also able to reverse direction to make cuts into and back out of foam pieces. Once a side has been completely cut, the block is rotated, and the machine continues the cutting process. The hot wire cutter produces products such as inserts for hot tub covers, packaging, and sheets of insulation. This machine also allows us to create lightweight architectural pieces like columns and crown moldings, and even toys like airplane gliders.

Compression Cutter

There are lots of uses for foam regardless of the industry. Whether for commercial use or residential use, foam offers a solution that is easy to install and affordable while also offering durability made to last. When it comes to creating the products you know and love from our inventory, we employ several types of machines in the process. With our foam compression cutter, we are able to provide you with all your needs at a faster rate without sacrificing on precision or shape. Let’s take a closer look at this machine.

There are lots of uses for foam regardless of the industry. Whether for commercial use or residential use, foam offers a solution that is easy to install and affordable while also offering durability made to last. When it comes to creating the products you know and love from our inventory, we employ several types of machines in the process. With our foam compression cutter, we are able to provide you with all your needs at a faster rate without sacrificing on precision or shape. Let’s take a closer look at this machine.

A hybrid machine – part die cutter, part convoluter – the foam compression cutter is able to produce highly individualized forms using pressured cuts made over templates. Coated pressboard molds, produced in-house, work much like the studded rollers on the convoluter by creating areas of differentiating pressure as the foam is forced against the template by rollers. The .04″ thick blade saws directly above the template as the foam is drawn through the machine.

The foam forms a mirror image of the template, with elevated areas on the template creating greater pressure, forcing more foam under the blade. This results in elevated areas on the foam once released from pressure, allowing us to create smooth, 3D contours. Best of all, the foam compression machine allows for multiple templates can be fastened to the table to produce identical products in a single run, much like the die cutter.

The foam compression machine is more cost-effective than creating similar products using molded techniques, as the templates can be produced much more quickly and at lower a cost. That cost is further reduced with our ability to create these templates in-house. This provides flexibility for economical fabrication in both high and low volumes. Examples of products created on the compression cutter include 3D cushions, bedding, and specialty packaging materials. As one of our more specialized machines, the fact that it can keep up with high volume orders makes it a mainstay in our factory.

Radius Cutter

As one of the most versatile materials on the market, foam can be used for a wide range of applications from boating seats to medical-grade lumbar supports. While most people think of foam as sheets, the need for precision cut foam is one of the biggest applications for this innovative material. When looking for an option with high levels of precision cut into them, our radius cutter is one of the go-to machines we employ to achieve the results you need. With the ability to create a precise cut on a variety of densities, the radius cutter is one of our most reliable machines in creating products for our valued customers. Let’s take a closer look at the reliable machine and the products it creates.

As one of the most versatile materials on the market, foam can be used for a wide range of applications from boating seats to medical-grade lumbar supports. While most people think of foam as sheets, the need for precision cut foam is one of the biggest applications for this innovative material. When looking for an option with high levels of precision cut into them, our radius cutter is one of the go-to machines we employ to achieve the results you need. With the ability to create a precise cut on a variety of densities, the radius cutter is one of our most reliable machines in creating products for our valued customers. Let’s take a closer look at the reliable machine and the products it creates.

When cutting foam in bulk, sometimes the matter of speed can lead to less even pieces, edges or cuts. Sometimes a machine may produce uneven edges or rougher corners. With the radius cutting machine, you get a clean, consistent cut throughout for a better product dimension wise. Our radius cutter handles jobs that require extra precision when forming smooth curves along outside edges. The radius cutter has its blade under tension to provide an angled cutting plane, with a block to keep a cut’s angle and depth from varying. After trimming all sides of the foam piece, it is then turned over and the process is repeated, resulting in a uniform radius along the product’s axis. The radius cutter features a self-tensioning .005″ stainless steel blade and a vertically adjustable cutting area, able to handle a range of thicknesses from 3″ to 7″. With a 48″ x 33″ table area, we can fabricate contoured seating cushions of nearly any size. We also use the radius cutter to make sponges. When it comes to creating rounded edges with clean lines and even dimensions, this is one of our most commonly utilized machines in our factory. Let us create something for your foam needs today using this reliable machine!